Hi friends today i will tell you about pcb

making of an electronic circuit. To temporary make the circuit some persons use

perforated boards to mount and shoulder the components. But to make

permanent circuit we use copper clad board so as to ensure less wear and tear

with the pcb. Some of you might have seen the pcb inside various electronics

equipment e.g., T.V. , Radio, etc. We will make pcbs similar to that with

perfect outline of the tracks as it has been manufactured from a company. Now

first of all you must know the circuit diagram of electronic gadget you

are going to make. The circuit schematic is drawn on the paper

with the pin connections of different terminals of electronics

components. The circuit diagram helps us for accurate making

of pcb layout with right pin connection.Now the express pcb software is used

for drawing the schematic in express SCH portion of the express pcb software

and after making,Its printouts is taken and the

circuit schematic is obtained in this way.For making the circuit

schematic you must install the express pcb software (Download here free).Now

after installation you will find two icons viz. expressSCH and expressPCB.The

former is used for drawing the schematic, Now double click the the

former icon and a window will appear showing various tools and drawing

area.You can choose any of the ICs and electronic component from the menu.The

component Menu comes when you click on the analog icon on the tool bar. Then

you choose the required component or IC. Now after choosing the correct item

you can place it on the work area.The component Menu contains various ICs with

their part numbers and company name also like Texas instruments

SN75160, Linear Technology LT1070, Atmel Microcontrollers, Microchip PIC

microcontrollers series ICs,and many more are there in the component Menu.You

can choose your desired ic of which you are going to make the circuit.The ICs

contains all the associated Pin with names Labeled. If the component is not

listed in the Menu Then You can create your own component using Various tools

in the tool bar, these component are at no.9,10,11 Position from the upper most

tool.Get the information of making the custom component in the Quick start

Guide of the Express SCH. You can connect the various components pins using the

Connecting wire Icon from tool bar at left.Now according to the Datasheets and

application notes of the components and ICs make the correct connection with

wire tool. When the circuit is complete you can print the whole circuit on

paper and obtain the schematic, and save the .sch file. Now double click on the

express PCB icon and you will find there a toolbar,Menu bar,In The toolbar you

will find a component Menu tool in the shape of an IC. You can then select the

proper component and place it on the work area.Different connectors and

different IC packages are available such as SOIC package,QFN

package,DIP Package ,etc.This Creates a versatile ways of designing your pcbs.

Now select the Wire tool for connecting different pins of the components, Also

you Can link your .sch file in the ExpressPCB for Pin Connecting aid.However it

is recommended in large circuit since the chances of wrong pin connection

are high as compared to small circuits.It is not necessary to link the .sch

file to ExpressPCB also it is not necessary that you draw schematic in

ExpressSCH for small circuit you can take a look at pin connection

by hand made schematic. For linking the .sch file go to File option in the

Menu bar and select 'Link schematic to PCB' .You can also configure the track

width and it curvness.It is recommended to use keyboard keys for

proper placement of component and wires for a perfect layout.Also the thermal

pad option is available and the top layer and bottom layer option is

available.You can make the custom components if it is not available in

the component list. For procedure of making the custom component see the 'Quick

guide of ExpressPCB' .Now after completing the layout Go to print option in the

File option in Menu Bar or use short cut keys ctrl+P. Here If you have

make the pcb layout in both top layer and bottom layer then you can choose

either one or both at a time.You must mention or choose the paper size for

printing like A4,A3 ,etc.The paper that you use for printing must be

a Butter paper or a magazine paper and the printer that you use must be the

Laser printer.If you Don't have a laser printer then select in the printer

option 'Windows XPS document writer' and click ok. You will get a .xps

file which you can take in pen drive and go to a photostat shop or

cyber cafe that have a laser printer and print the layout on the butter

paper or magazine paper. Always see the component datasheet for the proper size

of the package of ICs or component you are going to use in your circuit.Also

Read the Quick Guide of the softwares.Here is the Pcb Layout Of a Transmitter and

Receiver Circuit Using HT12D and HT12E and RF Modules in ExpressPCB.

Here is the pcb layout of Transmitter and

Receiver Circuit Using HT12D and HT12E and RF Modules which is ready for

printing.

The above layout

is from .xps file of the circuit.Now after printing the .xps file on Butter or

magazine paper.Keep the following list of items ready for pcb making-

:: Copper

clad board (desired size)

:: Ferric

chloride (depending on size of board, dissolve 10gm

in water for 50 by 30 copper clad board)

:: Electric

Iron

:: Thinner

:: permanent marker

(for error correction)

Now take

the copper clad board of the size a little greater than the pcb layout.Now cut

out the extra paper in the margin of the printed paper and then put in over the

copper clad board where the copper is present with the printed side touching

the copper surface.Before placing the paper rub the copper side of copper board

with the help of scotch-brite available in market and clean the board with the

help of cloth.Now pre heat the clothing iron for five minutes then place

it over the magazine or butter paper below which the copper board is

present.And apply lot of pressure and heat for 10 minutes and then take the

board carefully since it is hot.You will see that the paper has sticked to the

board then wash the paper with lot of water and remove the extra paper.You will

see that the toner has been transferred to the board i.e. the whose

layout has been transferred to the board.Also verify the design that all tracks

are right or not,if you find any incomplete track then correct it by

using permanent marker Keep the ferric chloride solution ready

and dip the printed board in the solution for fifteen minutes (Eaching

Process). Here are some snapshots-

Below is

the Dual H-Bridge for Motor direction control used in remote control car.Its

layout is not shown here.

Below is the PCB Layout of above circuit in express pcb.

Here is PCB layout from .xps file.

Here is the PCB in Ferric Chloride solution-

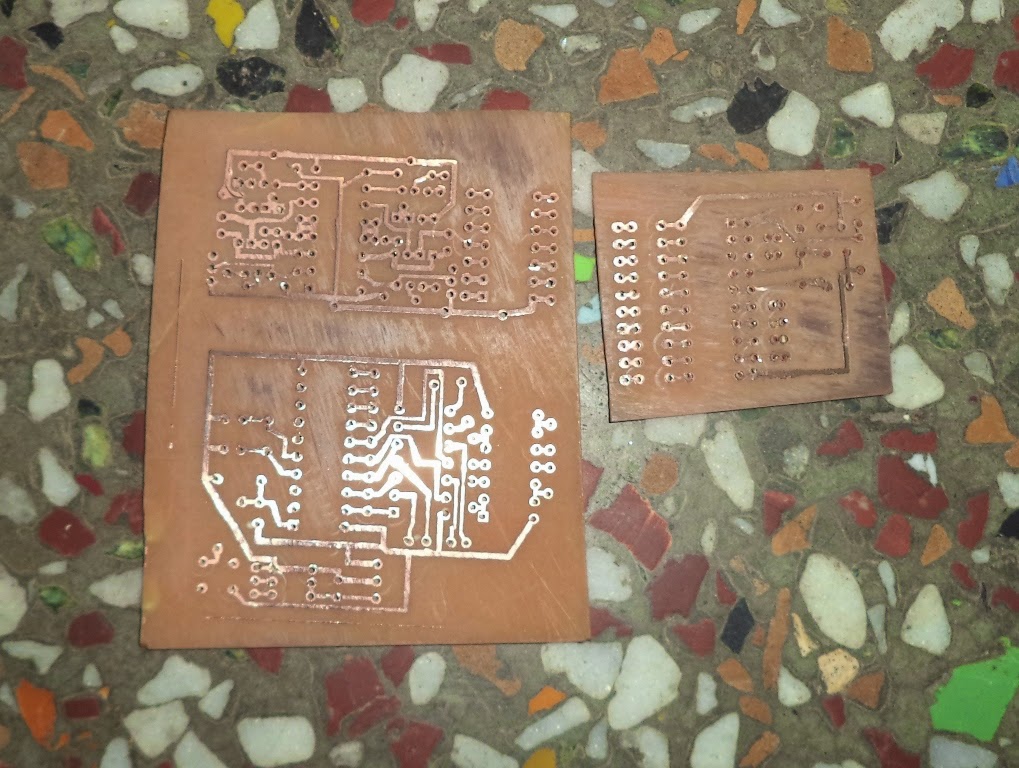

When Fifteen minutes has completed take out the pcb from the solution with the help of gloves and wash it with water.Now clean the pcb with thinner you Will notice that the extra copper has been removed and your pcb is ready for drilling.Drill the holes using hand drill or stand still drill at appropriate places where the components are to be placed. Use appropriate size of drill bit normally use 1mm bit.After drilling your pcb is ready to be used for placing components and shouldering.But before making the PCB layout of the circuit test the circuit on a breadboard.Here are the pcbs of the layout shown in this article.

Below is the H-Bridge circuit PCB.

Below is the Transmitter circuit PCB.

Below is the Receiver circuit PCB.

You can use the vast varieties of PCB designer software Only the difference lies is the operation of software but the procedure is same printing,transfering,eaching process etc. are same.Be careful with Ferric Chloride since it is highly corrosive.It is recommended to use gloves for treating with Ferric Chloride.