We often need to control the speed of DC Brushed motor in many situations.The commercially available speed controller are very costly so why not make a cheap motor speed controller easily at home.The main idea behind controlling the speed of DC Brushed motor is that the RPM or speed of Rotor of DC motor is directly proportional to the square of voltage applied across the terminals of the dc motor, hence by decreasing or increasing the voltage across the terminals of the motor we car easily increase or decrease the speed of the motor.Now question arises how to vary the voltage across the terminals of motor. A circuit can be designed to vary the voltage across the terminals of motor using some transistors and some potentiometer. Here is the circuit diagram-

The above circuit is the DC motor speed controller circuit in which two transistors are connected in dalington configuration. Here the list of components used-

:: one 10k ohm Resistor (R1)

:: one 10k ohm potentiometer or preset (RV1)

:: one 10 ohm resistor (R2)

:: one 2N3904 Transistor (Q1)

:: one MJE13003 Transistor (Q2)

:: one Brushed DC motor

:: connecting wires

:: Perforated or general board for mounting components

:: solder and soldering iron

The darlington configuration of the two transistors is obtained by connecting the Emitter of Q1 with the Base of Q2 and connecting both Q1 & Q2 collector together. Now the obtained configuration is darlington configuration which behaves as a single transistor whose base is the base of Q1 and the emitter is the emitter of Q2 and since the collector of both transistor are connected therefore it is the joined collector of the single behaving transistor as shown in the circuit diagram above. The most important property of a darlington configuration is the Hfe product property.

The Hfe of the dalington pair of the transistor as a whole is the product of the individual transistor's Hfe. Hence we get a large output for small change in base current of Q1. Also the 2N3904 is capable of handling about 500 mili amps of current also it get very hot when operated at extreme positions hence to eliminate this 13003 (Q2) transistor is used with 2N3904 (Q1) in dalington cofiguration in which the 13003 will sink all the current passing through the motor as it is capable of delivering maximum current of 3 amps. , Normally motor needs less than 1 amp. . If your motor is of higher current rating then you can replace 13003 (Q2) transistor with another suitable transistor which can deliver higher current then 13003 like 13007 ,etc,.

Now the darlington pair is properly biased by using voltage divider biasing technique with the help of a 10k ohm resistor and a 10k ohm potentiometer or preset. The potentiometer or preset is a device whose resistance can be varied in some specified limits by rotating the knob of potentiometer or by rotating the wiper of preset using screwdriver. Below is a potentiometer.

The potentiometer's knob will be used for the controlling speed of motor by rotating it. The middle terminal of the potentiometer or preset is the variable resistance terminal which is connected to the base of the transistor Q1 and other terminals are used for completing the biasing circuit of the darlington pair.The motor is connected at the terminals A and B as shown in the circuit.The emitter of Q2 is grounded through a 10 ohm resistor to regulate the flow of current through the motor. The current flowing through the motor is the sum of collector current through Q1 and Q2 transistor. But large quantity of current flows through the 13003 transistor. A small change in the value of current through the transistor's base Q1 brings large change in current and hence voltage across motor. So by rotating the knob of the potentiometer ,the resistance below R1 changes and hence the voltage across RV1 lower changes linearly consequently the voltage at the base of transistor Q1 changes which changes the base current of Q2 and hence voltage across Terminals A and B changes. Which changes the speed of the DC motor connected at terminals A and B.

Hence in this way the speed of the Brushed DC motor can be varied by just rotating the Knob of the potentiometer in the Circuit.

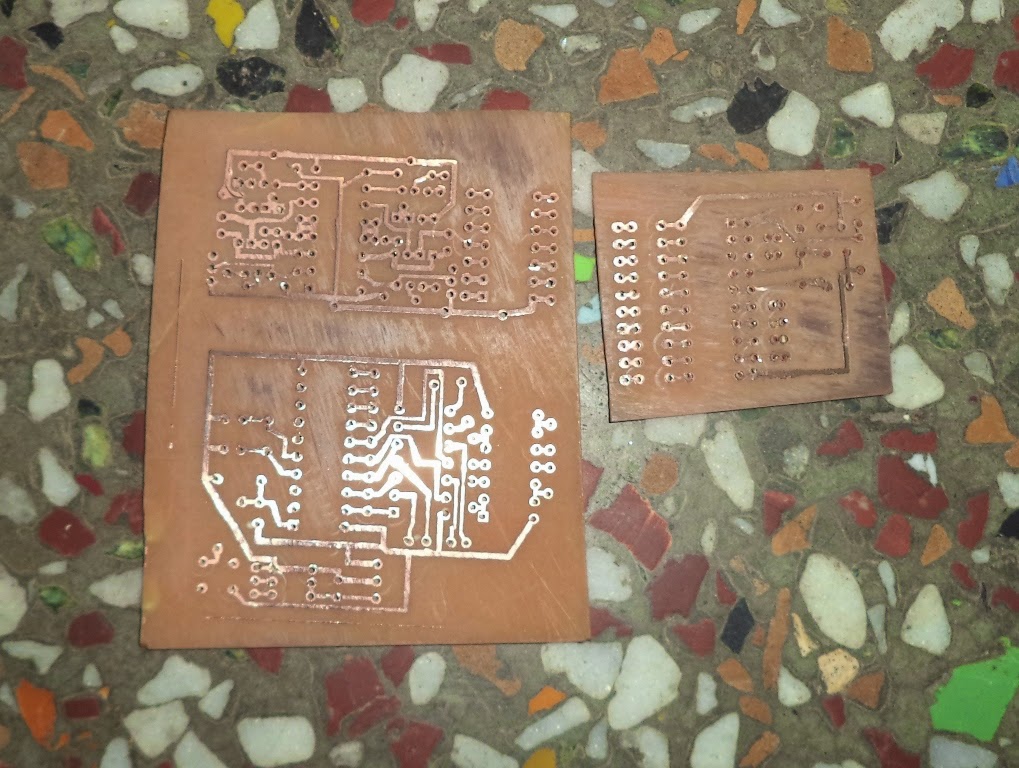

For making the physical circuit on pcb just place all the listed components in their proper place and connect as shown in the circuit diagram.For details about making pcb of circuit click here.